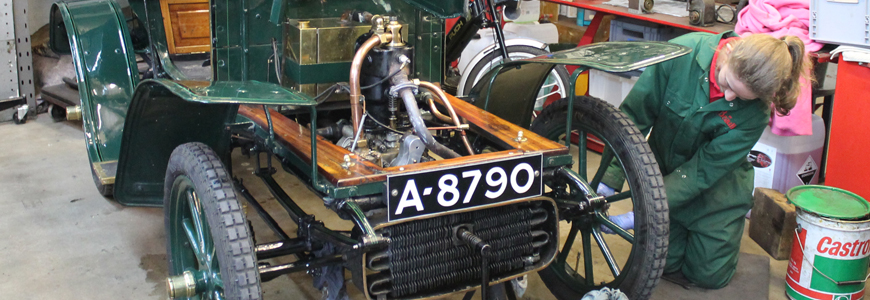

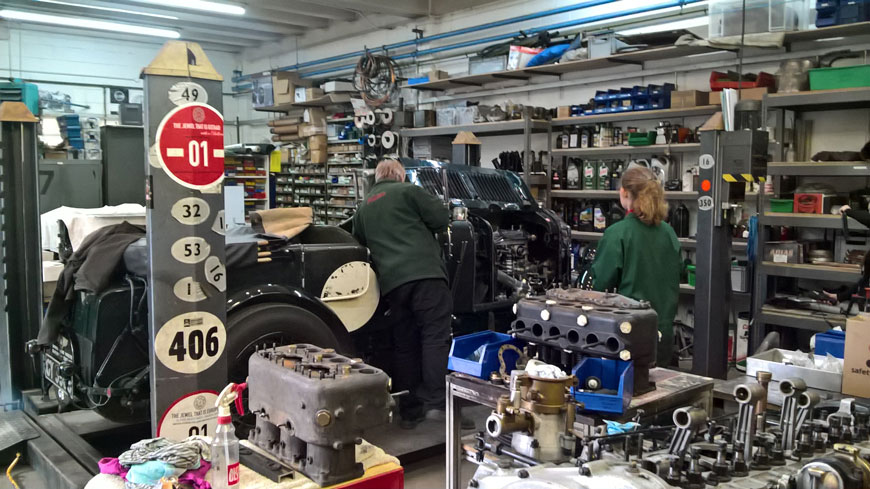

As workshop apprentice Emily Leese settles into her role at the National Motor Museum, she has been learning on the job with engineering challenges to fine-tune her new skills.

One of her first projects has been to prepare Beaulieu’s veteran cars for the London to Brighton Veteran Car Run and to become part of the back-up team providing support at this weekend’s event.

Getting Beaulieu’s Bentley 4½ litre supercharged Blower ready for display at InterClassics Brussels (November 17-19) has also offered the challenge to help reassemble its engine. All of these tasks and more are part of a day’s work in the National Motor Museum workshop.

On the London to Brighton run

Beaulieu and the Montagu family have a long tradition of taking part in the London to Brighton Veteran Car Run, the longest-running motoring event in the world. 2017 will be the first year for Emily to make herself part of that history.

Not only has she helped to prepare the four veteran cars being driven at Sunday’s event but she will be a key member of the National Motor Museum’s vehicle support team. Located at the half-way service halt, Emily will be helping to check over the cars as they arrive, replenishing fluids and carrying out any repairs that are needed at the roadside. As all of the museum’s cars are open-top, fingers crossed that the weather will be dry.

You can follow Emily’s experience of the London to Brighton Veteran Car Run on Twitter by following @Beaulieu_Hants throughout the event.

Mary Montagu-Scott, Lord Montagu’s sister and the High Sheriff of Hampshire, will be at the wheel of one of Beaulieu’s cars tackling the 60-mile challenge which celebrates the easing of restrictions on early motorists and commemorates the Emancipation Run of 1896. In total, more than 400 pre-1905 veteran cars will be taking part.

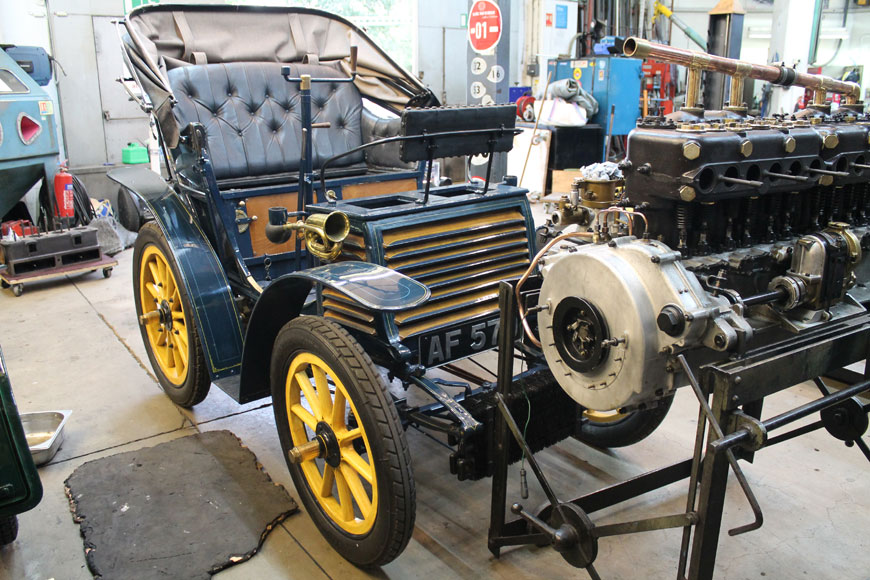

Emily has worked on the museum’s 1903 De Dion Bouton 6hp, one of Edward, Lord Montagu’s first historic vehicles which started the collection at Beaulieu, the 1904 De Dion Bouton 6hp and 1903 Daimler 22hp in preparation for the event. The 1899 FIAT 3.5hp, which can usually be seen on display in the museum, will also join the Beaulieu team.

Not surprisingly for vehicles of more than a century old, fastidious preparation is the key to reliability so the entire workshop team has been busy preparing the cars for their journey. As well as helping to change lubricants, greasing and adjusting mechanisms and fastidiously cleaning all of the cars’ paraffin-fuelled lamps, Emily has serviced the wheel bearings of the 1904 De Dion and adjusted the valves of the 1903 Daimler’s engine under the watchful eye of the museum engineers.

The only car of its type taking part, the 1899 FIAT has required more extensive preparation. The workshop team has constructed a new ignition system for the car’s two-cylinder engine, which should improve not only its running but reliability. With a conventional Lucas distributor extensively modified to suit, with ignition advancement and retardation controlled by a hand-made linkage, Emily has been able to watch this ingenious engineering solution taking shape. After the run, this will be removed and the original ignition system reinstated, in order to return the car to its original condition.

Blower Bentley back on the road

Another remarkable car that Emily has helped to get roadworthy is the 1930 Bentley 4½ litre supercharged Blower, which is back in action following the rebuild of its four-cylinder engine.

This Bentley is one of the National Motor Museum’s most popular and active vehicles and last winter it developed an ominous rattle, owing to worrying wear to the engine crankshaft and con rods which needed to be replaced.

After months of painstaking work by the workshop engineers, the reassembled engine was finally ready to be re-fitted in the car. Great care was required to line-up this heavy unit with its mounting holes on the chassis frame as it was lowered into place, so Emily helped engineer Mike Gillett with the careful process, before bolting the engine firmly into place.

Once the Bentley’s radiator and front end panels had been re-fitted, fine tuning of the engine could begin which provided another opportunity for Emily to learn from her colleagues. Finally, to let the rebuilt engine ‘run-in’, the Bentley was taken on a 401-mile road test; after all of the workshop team’s hard work, it of course behaved impeccably.

The iconic car will be part of the Big Five display by the five leading motor museums of Europe at InterClassics Brussels. For more details see www.beaulieu.co.uk/news/big-five-display-interclassics-brussels/.

Special arrival from Draper Tools

Each of the workshop engineers have their own tool chest, filled with the tools essential to carry out specialist work on Beaulieu’s historic vehicles. As the newest member of the workshop team, Emily has taken delivery of her own tool chest and tool kit, generously donated by Draper Tools . . . which has been the envy of her colleagues!

Now taking pride of place in the workshop, Emily’s bright red tool chest is brimming with a wide selection of tools chosen from the Draper Expert range. When working on delicate or difficult items, only tools of the highest standard will do the job, so this comprehensive selection of tools should mean that Emily has everything she needs as her apprenticeship gets underway. From sockets, spanners, hammers, chisels and screwdrivers, to a Vernier Caliper, mole grips, inspection lamps and goggles, this multitude of tools will be essential.

“It was like Christmas when it arrived,” said Emily. “At first, the other engineers would cheekily borrow tools from it but I think I’ve got them all back now!”

Museum Manager and Chief Engineer Doug Hill said: “When Senior Engineer Ian Stanfield and I started at Beaulieu in the 1970s, we were lucky to even have our own toolboxes, so this generous donation by Draper Tools will really help to get Emily started. No doubt she will add to it with even more tools over the years, along with all of the bits of old wire and broken mirrors that we have all put in our toolboxes over the years.”